Pharmaceutical desiccant packaging usually use silica gel or molecular sieve or two mixed desiccant, most of them are based on a mixture of silica gel and molecular sieves, and the ratio is adjusted according to the characteristics of the drug.

The feature of silica gel and molecular as follow:

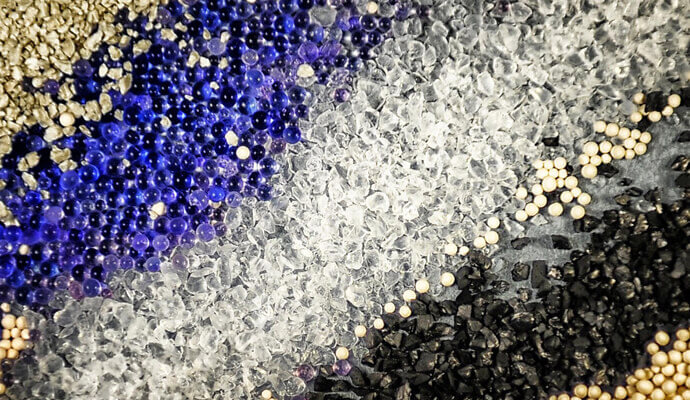

Silica gel desiccant is a highly active adsorbent material, usually prepared by reacting sodium silicate and sulfuric acid, and undergoing a series of post-treatment processes such as aging and acid foam. Silica gel is an amorphous substance with a chemical formula of mSiO2. nH2O. It is insoluble in water and any solvent, non-toxic and tasteless, chemically stable, and does not react with any substance except strong alkali and hydrofluoric acid. The most commonly used in pharmaceutical desiccant packaging is fine-pored silica gel, which has a white, translucent glass body. It is mainly used for drying and moisture proof, and can be used as a catalyst carrier and dehydration purification of organic compounds. Because of its high bulk density and low humidity, the moisture absorption effect is obvious. It can be used as an air purifier to remove moisture from the air to control the humidity of the air.

desiccant

Molecular sieve desiccant is a desiccant product that is artificially synthesized and has strong adsorption to water molecules. The pore size of the molecular sieve can be controlled by the difference in processing technology. In addition to adsorbing water vapor, it can also adsorb other gases. At high temperatures above 230 ° C, water molecules are well accommodated.

effervescent tablet tube

Effervescent tube manufacturers depend on the characteristics and storage mode of the drug when selecting the desiccant ratio.

Copyright © Shijiazhuang Xinfuda Medical Packaging Co., Ltd. All Rights

MAKE AN ENQUIRY