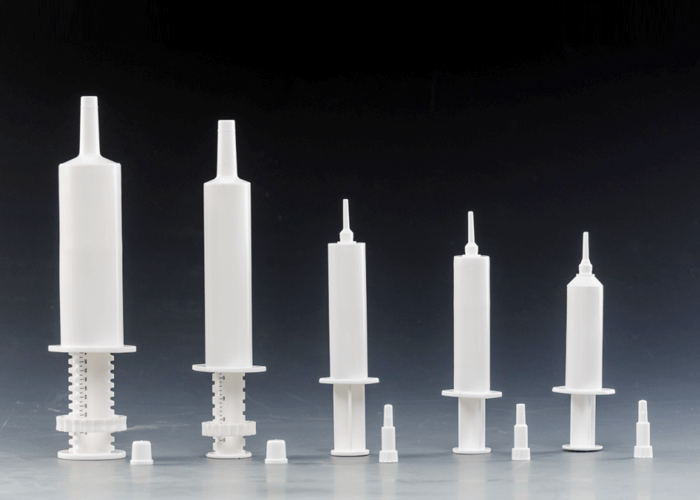

The plastic syringe assembly consists of a needle tube, a cap, a push rod or a piston. Each plastic component is produced using an injection molding process. Do you know the standard for the identification, packaging, transportation and storage of plastic veterinary syringes?

1 Logo

Each small package of dosing syringe products should have the following markings:

a) product names and trademarks;

b) plant name and site;

c) batch number, model specifications;

d) implementation of standard numbering;

e) production date;

f) In addition to the above marks on the large package of prefilled syringe products, the quantity should also be marked, "Afraid of Rain", "Afraid of Sun", and "Stacking Layer Limits"

Marks such as N = 8 ”shall comply with the relevant regulations of GB / T 191-2008.

2 Packaging

Carton boxes are used for outer packaging, plastic bags are used for inner packaging, and stored in a dry and ventilated place.

3 Transportation

Pay attention to sun protection and rain and snow during transportation. Do not mix with toxic or hazardous materials.

4 Storage

The storage environment requirements for pre-filled syringes should be a dry, well-ventilated room with no harmful or corrosive materials around.

Retest period: 24 months.

Copyright © Shijiazhuang Xinfuda Medical Packaging Co., Ltd. All Rights

MAKE AN ENQUIRY