As the daily use of household medicines and chemicals becomes more popular, the risk of children accidentally ingesting them is gradually increasing. In order to protect children under the age of 5 from the dangers of accidental ingestion, child-resistant packaging (CRP) came into being. The core goal of this type of packaging design is to ensure that children cannot easily open it, but adults (including the elderly) can still use it smoothly. Globally, the regulatory and certification standards for child-resistant packaging are constantly improving to ensure that the packaging can meet the needs of adults while protecting the safety of children.

28mm child resistant cap for liquid medicine

Regulatory requirements for child-resistant packaging in the United States

In the United States, the standards for child-resistant packaging are jointly regulated by the Consumer Product Safety Commission (CPSC) and the Food and Drug Administration (FDA). According to the CPSC, 16 CFR § 1700.20 requires that child-resistant packaging must be strictly designed to ensure that at least 85% of children under the age of 5 cannot open the package. In addition, the FDA requires that in the packaging test, at least 80% of children still cannot open it after demonstrating the opening method, while adults should be able to open it successfully within 5 minutes.

Child-resistant packaging standards in Europe

In Europe, child-resistant packaging is also regulated by strict regulations. The CLP (Classification, Labelling and Packaging) Regulation requires the use of child-resistant closures (CRC) for certain hazardous substances and mixtures. Such items typically include:

Chemicals with acute toxicity

Substances that cause systemic toxicity to target organs

Chemicals containing 3% or more methanol or 1% or more methylene chloride

To ensure that these packages are effectively childproof, Europe has a series of standards that regulate their design and testing.

EN ISO 8317 vs. EN 862

EN ISO 8317: This standard applies to reclosable child-resistant packaging and requires that the packaging cannot be opened by at least 85% of children during the initial test. When opened by adults, the packaging should be effortless and not challenging.

EN 862: Unlike ISO 8317, EN 862 applies to non-reclosable packaging and emphasizes the characteristics of preventing children from accessing hazardous substances.

EN 14375: Specifically for non-reclosable packaging of pharmaceutical products, ensuring that such packaging is child-proof.

The implementation of these standards ensures that the packaging of medicines and chemicals sold on the European market meets child safety requirements and effectively reduces the risk of accidental ingestion by children.

Differences between FDA and ISO standards

FDA's regulatory requirements focus on the packaging of dangerous goods such as medicines and chemicals, emphasizing the safety of packaging and child protection measures. Its testing protocol requires:

At least 85% of children cannot open the package within 5 minutes, and at least 80% of children cannot open it after 10 minutes.

The test samples involve 50 children and require coverage of multiple age groups.

In contrast, although the ISO 8317 standard also stipulates similar child protection requirements, its testing process is more flexible. ISO's tests usually evaluate 30 children at 3 locations, focusing on resealable packaging, aiming to ensure that the packaging is both child-proof and easy for adults to use.

Comparison of ISO and FDA certification processes

FDA certification process

FDA regulates child-resistant packaging through the Poison Prevention Packaging Act (PPPA). Manufacturers need to ensure that their packaging complies with FDA regulations and obtain a general certificate of conformity (GCC) to prove that their products meet the requirements. Although the FDA does not require third-party certification, manufacturers usually send their packaging to accredited laboratories for testing to ensure that safety standards are met.

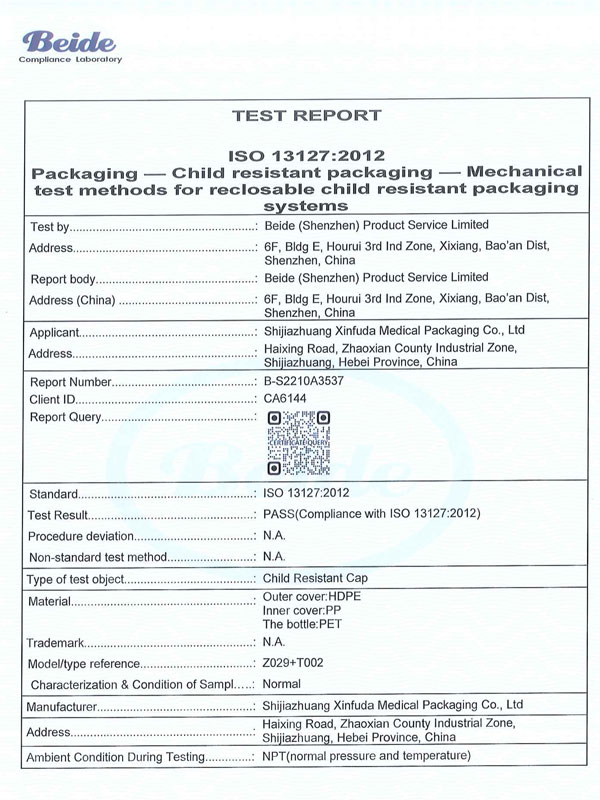

ISO Certification Process

Unlike the FDA, the ISO certification process is more international and standardized. According to the ISO protocol, products that pass the certification can be formally certified and widely recognized in multiple countries and markets. The ISO certification process requires manufacturers to submit packaging samples to accredited testing agencies, and after rigorous testing, they can be certified if they meet the standards.

HDPE bottle with child resistant closure

International differences in packaging safety

Although the standards for child-resistant packaging in the United States, Europe and other regions are different, their core goals are the same: to ensure the safety of children and prevent accidental ingestion. Some regions, such as the United States, emphasize the age distribution requirements during the testing process, while ISO pays more attention to the flexibility and wide applicability of the test. In addition, European standards such as the CLP regulation clarify which products must use CRC, further standardizing packaging design on the market.

In today's globalized world, multinational companies need to understand and comply with the certification requirements of different markets to ensure that their products can be sold globally. Child-resistant packaging that meets international standards can not only ensure the safety of children, but also increase consumer trust and enhance brand image.

As a key tool to ensure children's safety, child-resistant packaging has become an important part of the global pharmaceutical, chemical and household products industries. With the increasingly stringent regulatory standards and technological development, the design and certification procedures of child-resistant packaging are constantly being improved. Whether in the United States, Europe, or other markets, following relevant standards and certification processes is not only a legal requirement, but also an important manifestation of corporate social responsibility.

Copyright © Shijiazhuang Xinfuda Medical Packaging Co., Ltd. All Rights

MAKE AN ENQUIRY