There are many kinds of plastic syringes on the market, and the quality is different. How can we scientifically choose the most suitable plastic 10cc syringes?

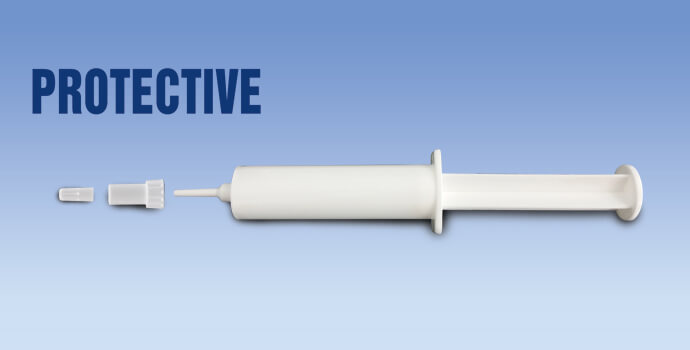

10cc syringe for gel

First of all, the current plastic syringe is mainly made of glass and plastic materials. The plastic gel syringes are gradually replacing the glass syringes. The main cost is lower, and the safety is higher than that of the glass syringes. Broken, relatively high-quality perfusion products, the production process itself is relatively advanced, generally using injection molding process to produce the perfusion device. The products produced by the injection molding process are molded at one time without any scraps, and the products are accurate in size and uniform in weight.

Secondly, the syringe has high sealing requirements. When selecting the syringe, the sealing property should be tested. Half of the water is injected into the syringe, the piston is inserted into the syringe, and the protective cap is removed to remove residual air. Then use the cap to block, apply an axial pressure of 30N on the pusher plug inside the syringe through the push rod for 30 seconds, and there should be no leakage at the cap seal and the piston seal.

Third, plastic syringes must be guaranteed to be sterility due to direct contact with the drug. Generally, the syringe should be produced in a clean workshop that meets national standards. In addition, in order to ensure sterility, if the veterinary drug manufacturer has sterility For higher requirements, additional ethylene oxide sterilization or cobalt 60 irradiation sterilization may be performed.

Copyright © Shijiazhuang Xinfuda Medical Packaging Co., Ltd. All Rights

MAKE AN ENQUIRY