When it comes to medicine packaging, safety is about more than just labels and expiration dates — it's also about keeping little hands out of dangerous places. That's where child-resistant packaging (CRP) comes in. And to make sure this safety feature is tested and standardized worldwide, we have international standards like ISO 13127.

28mm child resistant cap for liquid

So, what exactly is ISO 13127, and how does it shape the way pharmaceutical products are packaged and protected?

What Is ISO 13127?

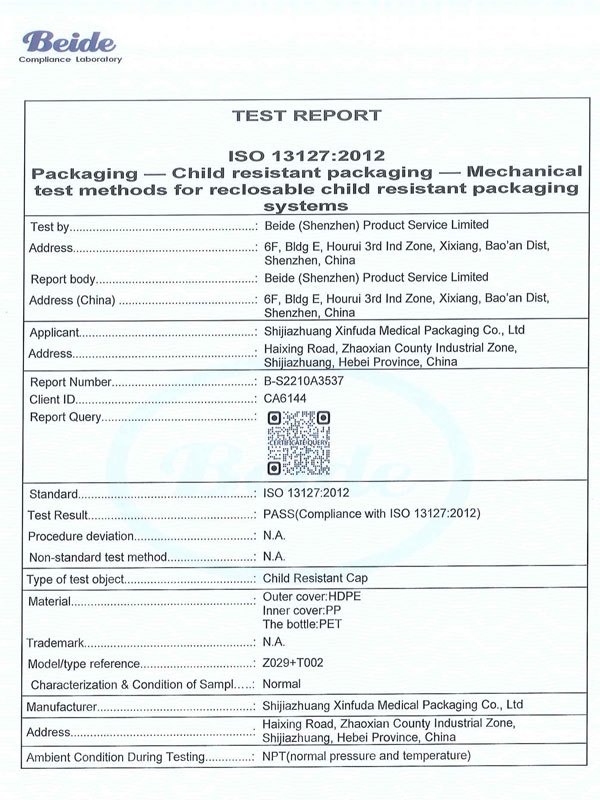

ISO 13127:2012 is an international standard that outlines mechanical test methods for reclosable child-resistant packaging systems. In simpler terms, it defines how packaging should be tested mechanically to prove that it's genuinely tough for children (typically under 52 months old) to open — but still usable for adults.

It works in conjunction with other standards like:

ISO 8317, which sets the performance requirements for CRP

EN 14375 (Europe) or 16 CFR §1700.20 (U.S.) for regional testing procedures

ISO 13127 supports the performance standard (ISO 8317) by providing reliable, repeatable lab tests that simulate human interaction.

What Does the Standard Cover?

ISO 13127 focuses specifically on mechanical testing procedures for CRP, which may include:

Torque tests – to evaluate the force needed to open a cap or closure

Pull and push tests – to measure how much effort it takes to remove or engage a part

Compression tests – to simulate squeezing by a child

Drop tests – to see if packaging integrity holds after being dropped

These tests help validate the design and performance of the package before it gets tested with actual children in usability studies (as per ISO 8317).

Why It Matters

Protecting Children from Harm

Accidental poisoning from medications and household chemicals remains a serious concern worldwide. CRP is a proven defense against these incidents, and ISO 13127 ensures that packaging meets a global safety benchmark.

Ensuring Product Consistency

Mechanical tests allow manufacturers to confirm the consistency of closures in mass production, helping to prevent defects or failures that could compromise safety.

Supporting Regulatory Compliance

For pharmaceutical companies selling in international markets, compliance with ISO 13127 (and related standards) can streamline regulatory approvals and minimize liability risks.

Balancing Safety and Accessibility

CRP must be difficult for children to open — but not for adults, especially seniors. ISO 13127 testing helps find that sweet spot between security and usability.

Real-World Application

Let’s say a pharmaceutical company is developing a new over-the-counter painkiller in a reclosable bottle. Before releasing it to the market, the closure system undergoes:

Mechanical testing per ISO 13127 to confirm torque resistance and opening force

Child panel testing per ISO 8317 to verify real-world effectiveness

Only after passing both levels of testing can the product be considered truly child-resistant and compliant.

Final Thoughts

Child-resistant packaging saves lives — but only when it’s designed, tested, and manufactured correctly. ISO 13127 plays a critical role in that process, offering a standardized way to ensure CRP does what it promises.

It might be easy to overlook packaging design when taking your daily meds, but behind every “push down and turn” cap is a world of thoughtful engineering and global safety standards working to keep families safe.

Need help interpreting packaging standards for your product or compliance project? Let me know — I can break down ISO requirements, generate test plans, or help with documentation.

Copyright © Shijiazhuang Xinfuda Medical Packaging Co., Ltd. All Rights

MAKE AN ENQUIRY